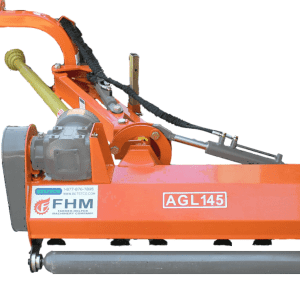

Farmer-Helper FH-AGL Standard Ditch Bank Flail Mower

SKU: FH-AGL125, FH-AGL145, FH-AGL165

![]()

Suitable for:

Brush up to 2″ thick

Comes with 14 oz Blades

![]()

Working Width

48″ – 65″

Powered By:

Tractor PTO

20- 65 HP

Playlist

Discover the unmatched capabilities of Ditch bank flail mowers – the ultimate heavy-duty solution for challenging landscaping tasks. Armed with potent cutting blades, these mowers effortlessly slice through heavy brush and wooded materials up to 2 inches in diameter. The mower head, attached to a hydraulic arm, enables you to maneuver the mulcher beyond your tractor’s wheels for optimal efficiency. With the head pivoting up to 90 degrees for hedge or hillside work, or down 60 degrees for ditch or bank work, this mower is truly the ultimate workhorse for any task.

Enhance the Ditch bank flail mower’s versatility by connecting it to an optional 4-way hydraulic control valve with a hydraulic float, allowing the mower to seamlessly follow the terrain’s contours. Unlike traditional mowers, a flail mower cuts finely and leaves the clippings on the ground where they were cut, making it an ideal choice for delicate and sensitive areas prone to damage from flying debris. This is why flail mowers are commonly employed in highway mowing and park maintenance, as they minimize the likelihood of throwing objects during cutting.

For a powerful and versatile solution to your rugged landscape maintenance needs, look no further than the Ditch bank flail mowers. Invest in the best and elevate your landscaping prowess to unparalleled heights!

- 4.5” Diameter Rotor Shaft

- Multiple Drive Belts Assure Power to the Blades

- Under Deck Clump Busters

- Standard 3-Pt Category I Hitch Mount

- Shear Bolt PTO Shaft for Standard 1-3/8” 6-Spline PTO

- PTO Driveline Included Free of Charge

- Balanced Rotor and Shaft to Reduce Vibration & Reduce Bearing Wear

- Powder Coat Paint Finish

Overall Width of Ditch Bank Flail mower: The Farmer-Helper AGL series has an overall width of 54″ to 71″ depending on the size of the unit.

Cutting Width of Ditch Bank Flail mower: The Farmer-Helper AGL series has a tilling width of 48″ to 65″ depending on the size of the unit.

Weight: The Farmer-Helper AGL series has a weight of 675 lbs to 895 lbs depending on the size of the unit.

HP Requirements at PTO: The Farmer-Helper AGL series requires 20 – 65 PTO horsepower depending on the size of the unit.

Cutting Height: The Farmer-Helper AGL series has a 0″ – 6″ Adjustable to meet various height requirements

Housing Material Thickness: The Farmer-Helper AGL series has a housing of 3-4mm thick.

Side Plate Thickness: The Farmer-Helper AGL series has a side plate thickness of 1/4″.

Blade Type: The Farmer-Helper AGL series uses a standard hammer blade. Each hammer blade weighs 14 oz made of cast steel (cast steel is much more durable than cast iron). Use the hammer blades for clearing saplings (2″ diameter or less).

Number of Blades: The Farmer-Helper AGL series uses 20 – 28 hammer blades depending on the size of the unit.

Precision Blade Overlap: On the Farmer-Helper AGL series the blades are staggered precisely with no gap in the mowing area. Blade overlap is important to achieve an even cutting result.

Rotor Rotation – Reverse: The rotor spins in the opposite direction as the wheels of the tractor when traveling forward. This allows the blades to shear the material as it is folded forward by the mowers. The material is then thrown up and over the rotor.

Rotor Tube Diameter: 4 1/2″- Heavy-duty steel tubing for long life.

Balanced Rotor Tube: The rotor tube is balanced to reduce vibration and ensures that the mower runs smooth, and reduces wear on the bearings.

Hitch Type: Category 1 standard 3-point.

Pivot Offset From Center Mount: This feature allows for an offset from the center to the right of the tractor. This feature is helpful for mowing around fences, buildings; walkways, etc. From the center of the PTO, the mower extends 44″ to 61″ depending on the size of the unit.

Hydraulic Offset: The hydraulic cylinder permits the carrier frame to be moved under your command. This permits you to control the cutting position of the mower. Designed so that you can get around rows, trees, fence lines, or whatever else is in your path. This can be connected to an optional Remote Hydraulic Control Valve designed to power the cylinder (also known as a 2-way valve) or to the rear remote on your tractor design to power the cylinder. Hydraulic Requirements: Hydraulic sources must be constant flow for powering Control Valve. We recommend the use of Front Loader Style Control Valve with Float Option. Float spool connected to the vertical pivoting cylinder will allow the mower to float and naturally follow the ground contour.

Drive Belts: The Farmer-Helper AGL series uses 3 – 4 belts, depending on the size of the unit.

Gearbox Rating: Up to 65 hp. Heavy-duty proved oil bath gearbox for long life.

Driveline / PTO Shaft: Shear Bolt PTO Shaft for Standard 1-3/8” 6-Spline PTO

Finish: Baked-on powder coat, powder coat is superior to paint.

Support Before and After the Sale: At Betstco our service department is staffed with professional technicians that inspect each machine before it is shipped. This ensures that you get a trouble-free machine from the get-go. When you need technical help or parts, our courteous staff can help you get what you need from our fully stocked warehouse. We keep a full line of replacement parts, and we can ship parts within 24 hours.

FLOAT AND NON-FLOAT CONTROLLER DESCRIPTION: The Float controller serves two functions. First, if your tractor has only one remote hydraulic port (2 hoses) you can use the float control as a splitter. 4 hoses from the machine plug into the controller and the controller is powered by the single port from your tractor. You can mount the control within reach of the tractor’s driver seat. The other function of this controller is you can plug the tilt cylinder into the float port and the mower will follow the contour of uneven ground.

Float controller can do the splitter function and float function.

The non-float controller can only be used for the splitter function.

These machines require a tractor that has 2 rear remote hydraulic ports (4 hoses), or a single hydraulic port (2 hoses) if you get the optional float or non-float valve controller.

| Spec | FH-AGL125 | FH-AGL145 | FH-AGL165 |

| Working Width | 48” | 57” | 65” |

| Overall Width | 54” | 63” | 71” |

| Min. HP Req. | 20 HP+ | 25 HP+ | 30 HP+ |

| Min Weight Tractor/ Loader | 3400 lbs | 4000 lbs | 4600 lbs |

| Hitch | Cat I | Cat I | Cat I |

| Gear Box Rating | 65 HP | 65 HP | 65 HP |

| Pivot Offset | 44” Right | 53” Right | 61” Right |

| Std Hammer Blades | 20 Hammer Blades | 24 Hammer Blades | 28 Hammer Blades |

| Housing Thickness | 3mm | 4mm | 4mm |

| Side Plate Thickness | 1/4” | 1/4” | 1/4” |

| Rotor Dia. | 4” | 4” | 4” |

| Rotor Shaft Dia. | 4 1/2” | 4 1/2” | 4 1/2” |

| Blade Swing | 14” | 14” | 14” |

| No. of Belts | 3 Belts | 3 Belts | 4 Belts |

| 3pt Conn. Width | 28” – 29” | 28” – 29” | 28” – 29” |

| Driveline Type | 6-Spline W/Shear Bolt | 6-Spline W/Shear Bolt | 6-Spline W/Shear Bolt |

| Weight | 675 lbs | 751 lbs | 895 lbs |

| Crated Weight | 699 lbs | 775 lbs | 975 lbs |

Who is Farmer-Helper?

Farmer Helper Machinery Co., Ltd (FHM) was established in 2009. The factory area is more than 20,000 square meters and houses 4 Metal laser cutting machines and more than 80 processing machines.

FHM manufactures a full range of high-quality implements for small to medium-sized tractor owners across the world. Farmer’s Helper has become an integral manufacturing premise for agricultural machines. Our team’s priority is customer success and satisfaction. We constantly improve our machines to meet customer demands and expectations.

Submit your review | |

1 2 3 4 5 | |

Submit Cancel | |

I been using my Ditch Bank AGL 165 for 2yrs now , great cutting machine. I use it around my ponds and it does a great job

Very Impressed with this! I replaced my Rotary cutter with this and I find that I can cut much heavier material with less power. It also produces a better finish leaving smaller debris. The reach of the ditch/bank mower allows a much wider use also.

Secondary notes:

The mower was crated nicely in a welded steel crate, however fedex still managed to bend up the crate. No damage other than a few scratches. I requested a lift gate on the order, however fedex showed up without it. I was able to use my pallet forks to remove it from the trailer and I was refunded the lift gate charge without issue.

Had a small problem with the stand on one side of the small arm welded on wrong side. Jason handled the problem to my satisfaction with no hassle, i was so pleased i came back later and ordered a 6 ft finish mower from him. His prices cant be beat and the equipment is good quality.